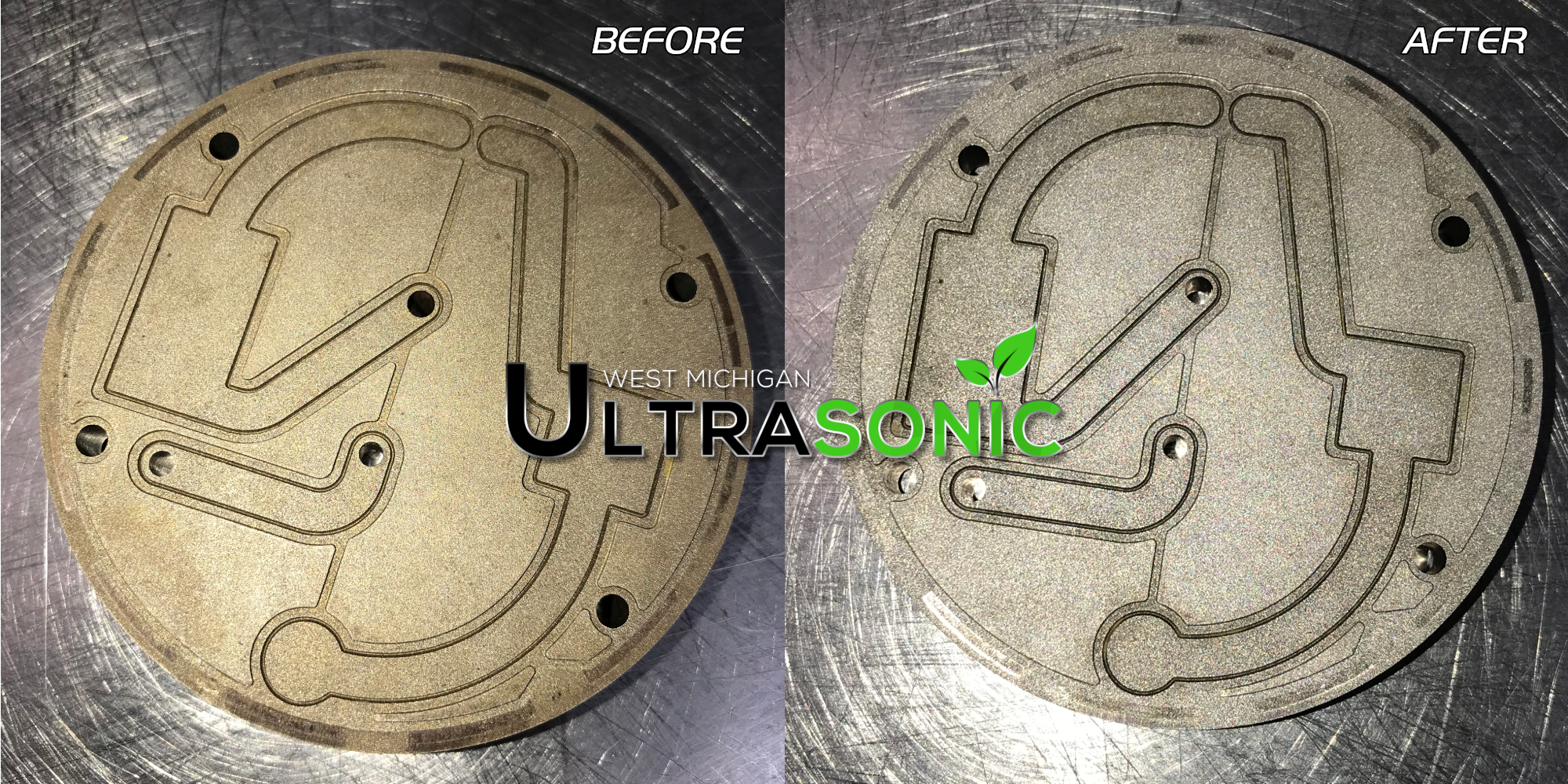

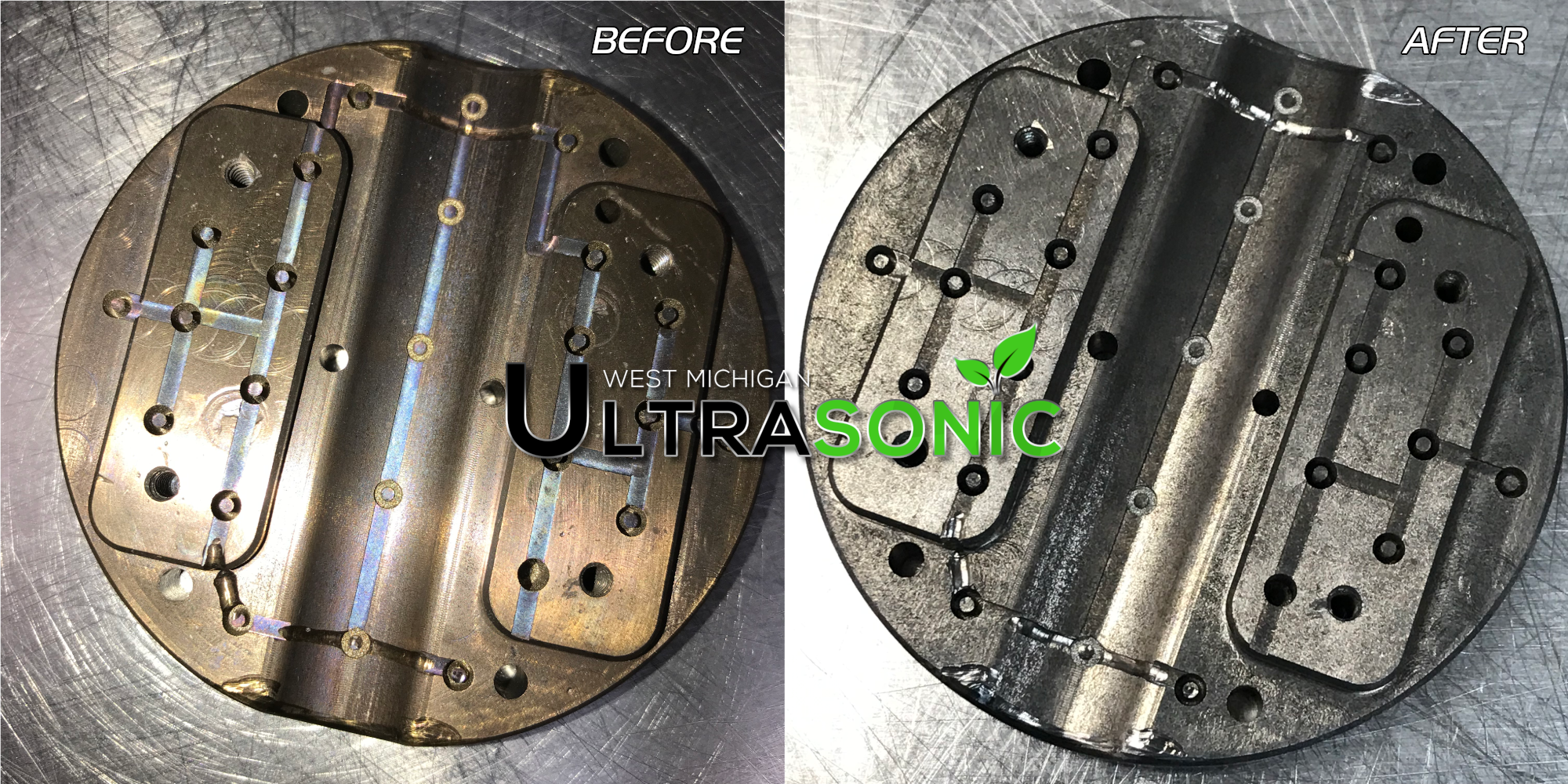

Professional Ultrasonic Plastic Injection Mold and Tool Cleaning Services. We thoroughly Clean Porcerax Steel Inserts, Injection Molds, Tooling, Blind Port Holes, Small Blind Cavities without Damaging or Changing the Surface Finish.

Our ultrasonic cleaning process addresses the challenges associated with Plastic Mold Insert and Tool cleaning and maintenance. Release agents, carbon, plastic residue are effectively removed from complex inserts and intricate surfaces. We have fast turn around times, variety of Industrial Cleaning Chemicals specifically designed for plastic injection mold applications. We enjoy helping local businesses significantly reduce labor costs on difficult cleaning and maintenance work. Our Ultrasonic Cleaning Equipment handles the most difficult Manufacturing Maintenance work with ease. Cleaning Plastic Molds, Inserts, Valves and other key components and tools in the Injection molding process has many challenges depending on application. Release Agents, Material Type, Temperature, Carbon Build Up, Complex Inserts with Intricate Surfaces needing cleaning and many other factors are no problem for our Ultrasonic Cleaning Equipment. Contact Us and discover how we can provide superior cleaning results on your most labor intensive cleaning jobs.

Specialized Ultrasonic Cleaning Processes and Commercial Ultrasonic Cleaning Chemicals deliver Professional Results.

Ultrasonic Plastic Injection Mold Cleaning SErvice Results - Before

Ultrasonic Plastic Injection Mold Cleaning SErvice Results - After

GET AN ULTRASONIC Plastic Injection Mold and Tool CLEANING QUOTE TODAY!

Fill out our easy “CLEAN IT” Email Form and receive an estimate today.

Ultrasonic Clean Porcerax Steel Mold Inserts and Valves for plastic mold manufacturing.

Also known as Permeable Mold Steel, Porcerax vents gases during the molding process. During production, the pores get plugged up and venting decreases causing defects in parts. Our ultrasonic cleaning process effectively cleans the outer surface as well as the inner pores of the tooling. Our ultrasonic clean process uses environmentally friendly cleaning solutions. Other cleaning processes use highly toxic chemicals and additional handling of the expensive tooling increasing the risk of damage.

Importance of Tooling MAintenance

Maintaining tooling properly is extremely important to producing quality parts at high volumes. The challenge is the labor associated with maintenance. West Michigan Ultrasonic provides fast, affordable cleaning services to manufacturing companies. Contact us today for more information.